China Prototype Manufacturing: A Comprehensive Guide

The manufacturing landscape has undergone significant transformation over the past few decades, and one of the most prominent developments has been the rise of China prototype manufacturing. China has established itself as a world leader in manufacturing through innovation, advanced technology, and a skilled workforce. This article delves into the intricacies of China’s prototype manufacturing scene, highlighting its benefits and how businesses can leverage these advantages.

Understanding Prototype Manufacturing

Prototype manufacturing refers to the process of creating a preliminary model of a product to evaluate its feasibility, design, and functionality before mass production. This essential step can save companies time and costs, allowing them to refine their product to meet market demands. The key importance of prototype manufacturing lies in:

- Product Validation: Confirming that a product meets design specifications and functional requirements.

- Design Iterations: Allowing for quick modifications based on feedback from testing.

- Cost Efficiency: Identifying potential issues before mass production can significantly reduce costs.

The Advantages of China Prototype Manufacturing

China prototype manufacturing offers numerous advantages that attract businesses around the globe:

1. Cost Effectiveness

One of the most compelling reasons for choosing China prototype manufacturing is the lower production costs. Labor and material costs in China are typically lower than in Western countries, allowing companies to produce high-quality prototypes without overextending their budgets. This aspect is crucial for startups and small businesses looking to innovate without massive financial risks.

2. Advanced Technology and Equipment

China is at the forefront of modern manufacturing technology. The country boasts state-of-the-art machinery and tools, enabling manufacturers to produce highly precise and complex prototypes. This technological advancement not only enhances quality but also accelerates the production process.

3. Skilled Workforce

The nation is home to a large pool of skilled workers, trained in various manufacturing techniques. This expertise is invaluable in prototype development, where attention to detail and innovation are paramount. Engineers and designers in China are well-versed in the latest industry trends, which can significantly benefit foreign businesses looking to prototype new inventions.

4. Rapid Turnaround Times

In today’s fast-paced business world, time is of the essence. Chinese manufacturers have streamlined their production processes, which means they are often able to deliver high-quality prototypes in shorter time frames than their competitors. Quick turnaround times allow businesses to move faster from concept to market.

5. Comprehensive Services

Many companies in China offer a one-stop solution for prototype manufacturing. They provide extensive services, including:

- Design and Engineering Support

- Material Selection Guidance

- Testing and Quality Assurance

- Logistics and Shipping Solutions

This capability minimizes the hassles associated with managing multiple vendors and ensures greater efficiency.

The Prototype Manufacturing Process in China

Understanding the steps involved in the prototype manufacturing process can aid businesses in navigating their projects more effectively. Here’s a typical workflow:

1. Product Concept and Design

The process begins with a clear product concept. Engineers and designers collaborate with clients to finalize the design specifications and develop a blueprint or CAD model. This stage is pivotal, as a well-thought-out design lays the groundwork for successful prototyping.

2. Material Selection

Choosing the right materials is critical for the success of any prototype. In China, manufacturers offer a range of material options, including metals, plastics, and composites. Depending on the product’s requirements, the manufacturer will recommend materials that ensure the prototype performs as intended.

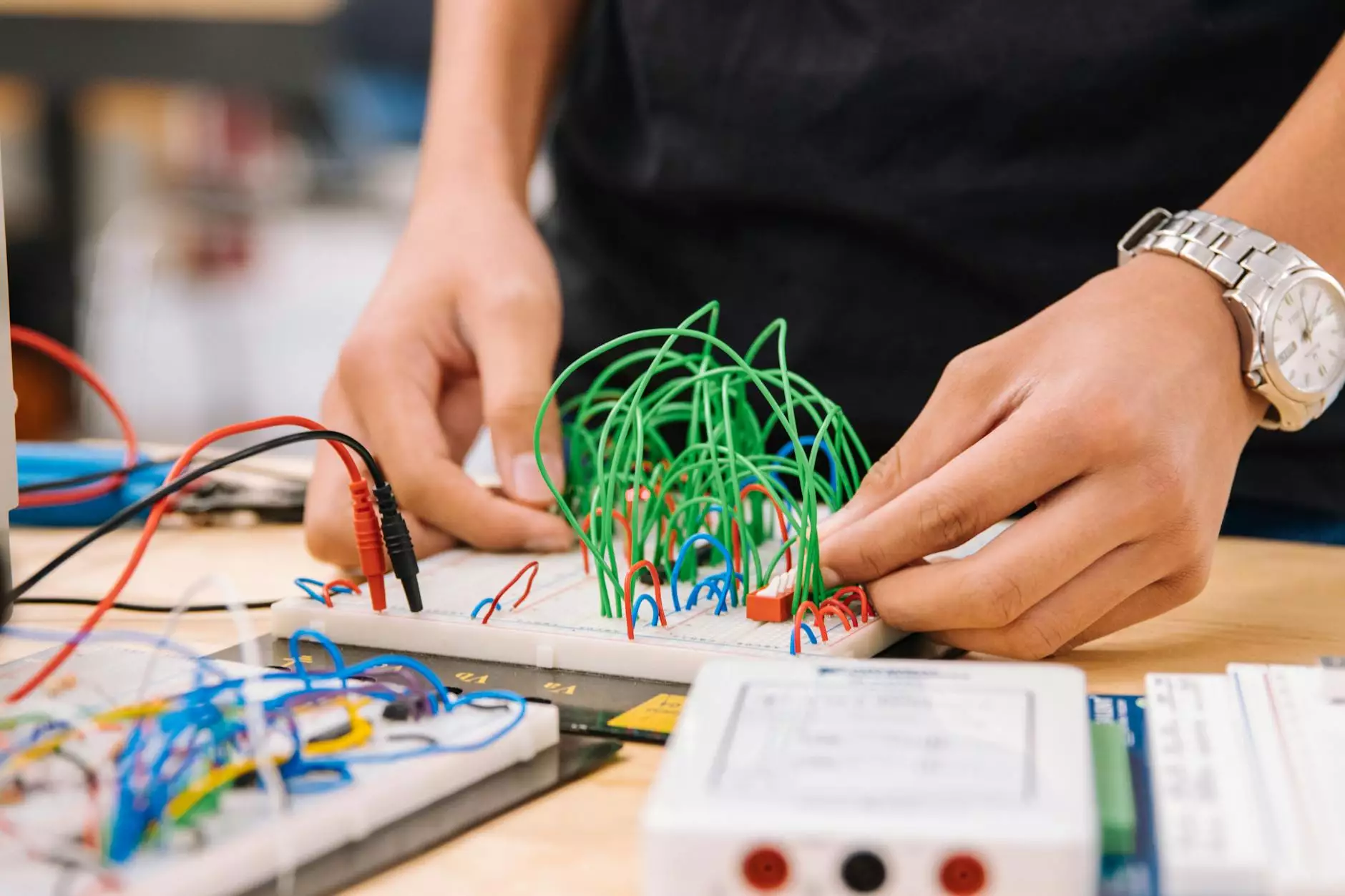

3. Prototype Fabrication

Using advanced machining techniques such as CNC machining, 3D printing, or injection molding, manufacturers create the prototype based on the approved designs and selected materials. This phase demands precision and quality control to ensure the prototype matches the desired specifications and functions correctly.

4. Testing and Iteration

Once the prototype is fabricated, it undergoes rigorous testing to evaluate its performance and identify any potential issues. Feedback from testing allows for necessary modifications, ensuring that the final product meets all functional and aesthetic requirements.

5. Finalization

Upon successful testing and iteration, the final prototype is prepared for approval. Once clients are satisfied, they can proceed to mass production, where the insights gained from the prototype stage will minimize risks and enhance overall production efficiency.

Challenges in China Prototype Manufacturing

While there are significant advantages to China prototype manufacturing, it’s also important to consider potential challenges. Addressing these challenges proactively can lead to smoother project execution:

1. Communication Barriers

Language differences can lead to misunderstandings, but many Chinese manufacturers now employ staff fluent in English to facilitate better communication. It's beneficial for businesses to establish clear channels of communication from the outset.

2. Quality Control

Ensuring consistent quality can sometimes be a concern in large-scale manufacturing environments. Partnering with reputable manufacturers known for their quality control processes is essential. Regular quality inspections and clear specifications can help mitigate risks.

3. Intellectual Property Protection

Concerns regarding intellectual property (IP) theft are prevalent in the manufacturing industry. Companies should take protective measures, such as implementing Non-Disclosure Agreements (NDAs) and working with manufacturers that have a strong track record of respecting IP rights.

How to Choose the Right Manufacturer in China

Selecting the right manufacturer is crucial for successful prototype development. Here are key considerations:

1. Research and Reviews

Conduct thorough research on potential manufacturers. Look for reviews, case studies, and testimonials from previous clients. Websites like DeepMould provide useful insights and can be a valuable resource in evaluating a manufacturer’s capabilities.

2. Quality Assurance Policies

Inquire about the quality assurance processes the manufacturer has in place. Understanding their approach to quality control will provide reassurance regarding the standard of products they deliver.

3. Responsiveness and Communication

A responsive manufacturer who is willing to communicate openly is essential. This relationship will be critical throughout the development process, and having access to someone who understands your needs can save a lot of hassle.

4. Capabilities and Expertise

Assess the manufacturer’s capabilities in terms of technology and expertise. Review their technical know-how and past projects to ensure they can meet your prototype demands effectively.

5. Pricing Structures

While cost shouldn’t be the sole determinant, understanding the pricing structure is important. Get detailed quotes and ensure that there are no hidden costs.

Conclusion

In conclusion, China prototype manufacturing stands out as a viable option for businesses seeking efficient, cost-effective, and high-quality prototype solutions. By tapping into China’s advanced technology, skilled workforce, and comprehensive services, companies can significantly reduce the risks and costs associated with product development. Whether you're a startup with a groundbreaking idea or an established company looking to innovate, working with a well-chosen manufacturer in China can provide the support you need to take your product from concept to reality, faster and more efficiently. For businesses focused on metal fabricators and needing reliable prototype manufacturing services, exploring options with DeepMould could be the start of a fruitful partnership leading to success in today’s competitive marketplace.